Plasma Sterilizer PS-140 Ver. 0 (2013-2015)

A Plasma Sterilizer is a low-temperature sterilizer intended to be used in clinics and hospitals to sterilize the medical instruments. This device uses Hydrogen Peroxide as a disinfectant and applies HV / LF plasma into its main chamber that is a high vacuum chamber to complete the sterilizing process.

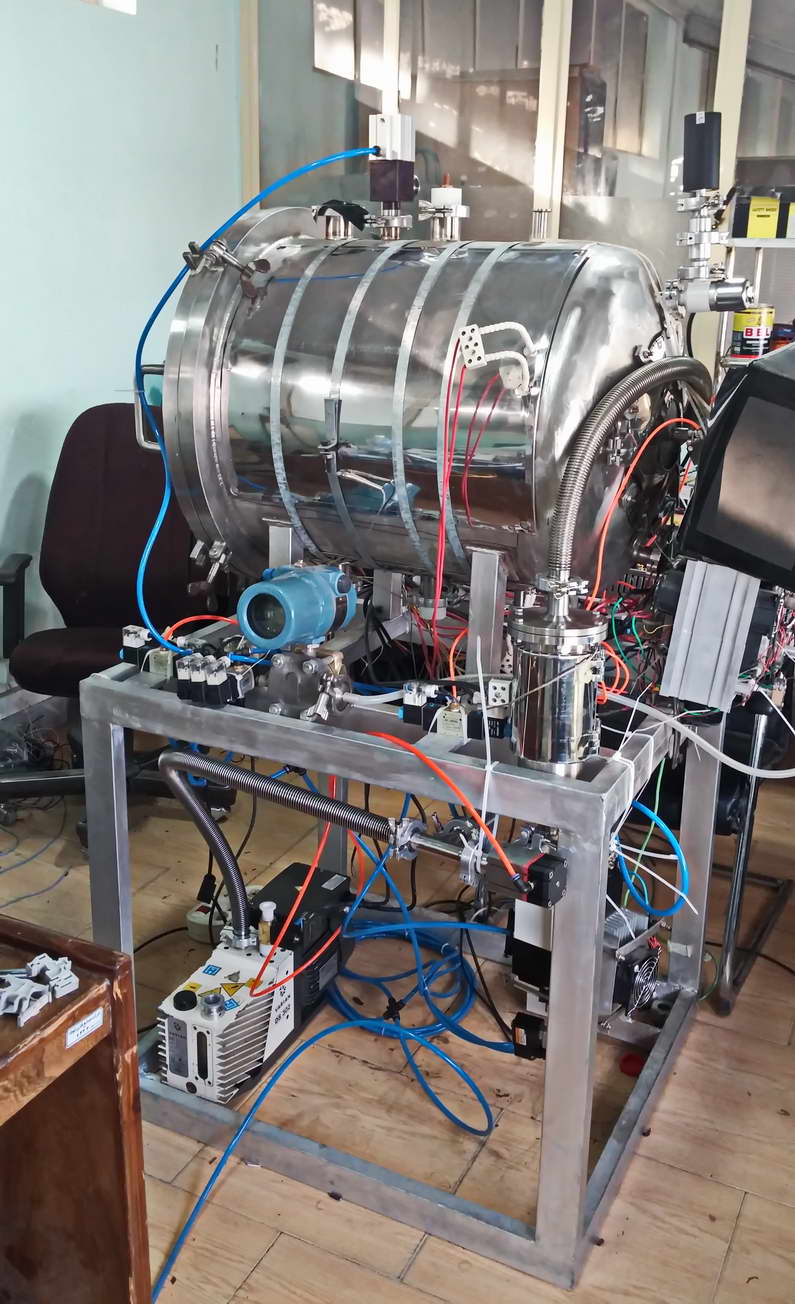

This project was started in 2013 and we studied about this device in about 3 years and made a prototype of the sterilizer in 2015 in Kousha Metal Industries company.

The project needs many professions, so much knowledge and a high level of production quality.

So this one was our favorite one :-D

At first, we studied plasma and plasma generators and tried to build one.

A Plasma Sterilizer is a low-temperature sterilizer intended to be used in clinics and hospitals to sterilize the medical instruments. This device uses Hydrogen Peroxide as a disinfectant and applies HV / LF plasma into its main chamber that is a high vacuum chamber to complete the sterilizing process.

This project was started in 2013 and we studied about this device in about 3 years and made a prototype of the sterilizer in 2015 in Kousha Metal Industries company.

The project needs many professions, so much knowledge and a high level of production quality.

So this one was our favorite one :-D

At first, we studied plasma and plasma generators and tried to build one.

We tried these circuits in the above vacuum chamber that we built. The result was this tiny little plasma.

Then we tried to build a rectangular chamber that was not successful :-(

The third one was better and it was a cylindrical chamber too and the plasma was so better than the first one:

The Evaporator:

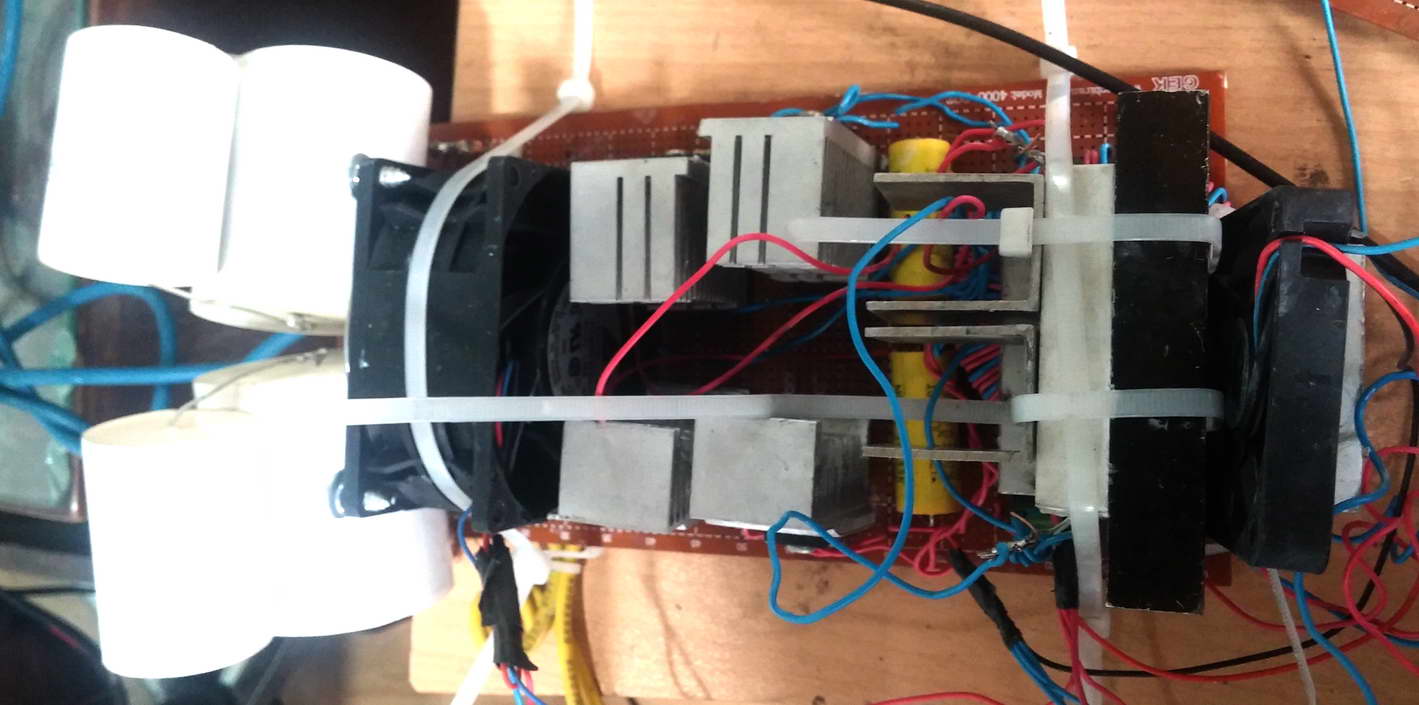

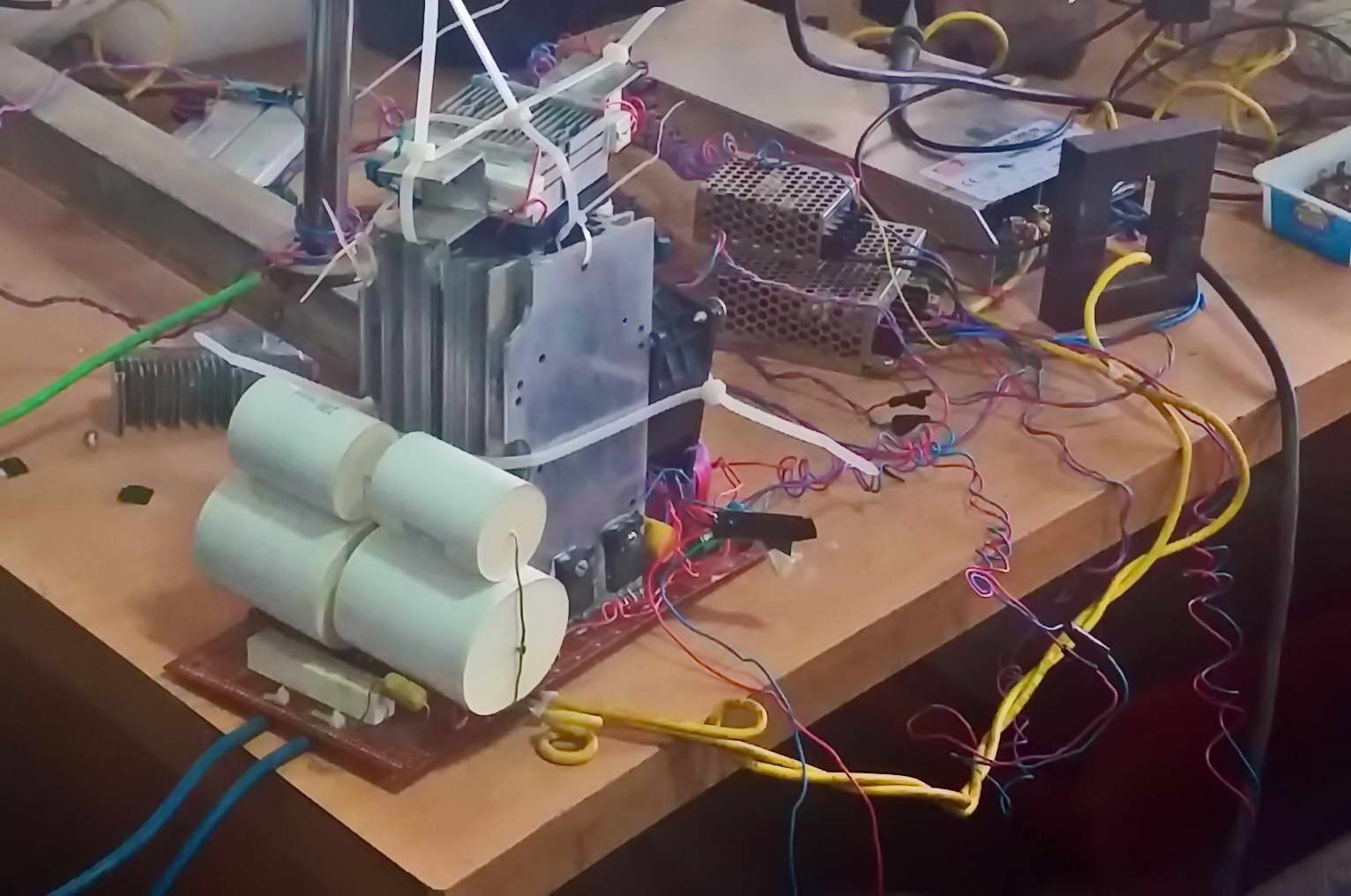

Since we wanted to build the whole device we have to work with hydrogen peroxide and its effects on microorganisms, we tried to design a process that injects hydrogen peroxide inside the chamber. The program has been written in two PLCs. One to control the temperature of the chamber and another one to control the digital outputs. We modeled and then built a structure with aluminum that this structure could be heated up to 70 degrees and could be cooled to temperatures below than 10 degrees. Later we change it to a structure that could concentrate the Hydrogen Peroxide.

Since we wanted to build the whole device we have to work with hydrogen peroxide and its effects on microorganisms, we tried to design a process that injects hydrogen peroxide inside the chamber. The program has been written in two PLCs. One to control the temperature of the chamber and another one to control the digital outputs. We modeled and then built a structure with aluminum that this structure could be heated up to 70 degrees and could be cooled to temperatures below than 10 degrees. Later we change it to a structure that could concentrate the Hydrogen Peroxide.

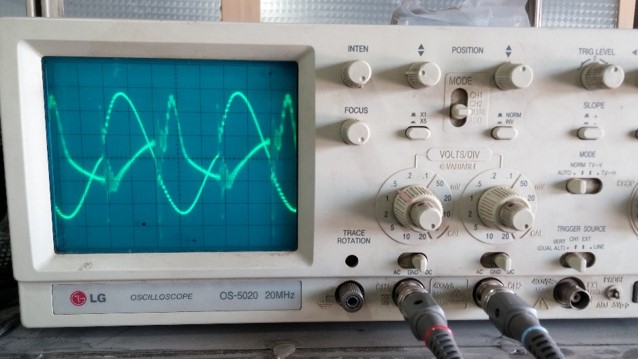

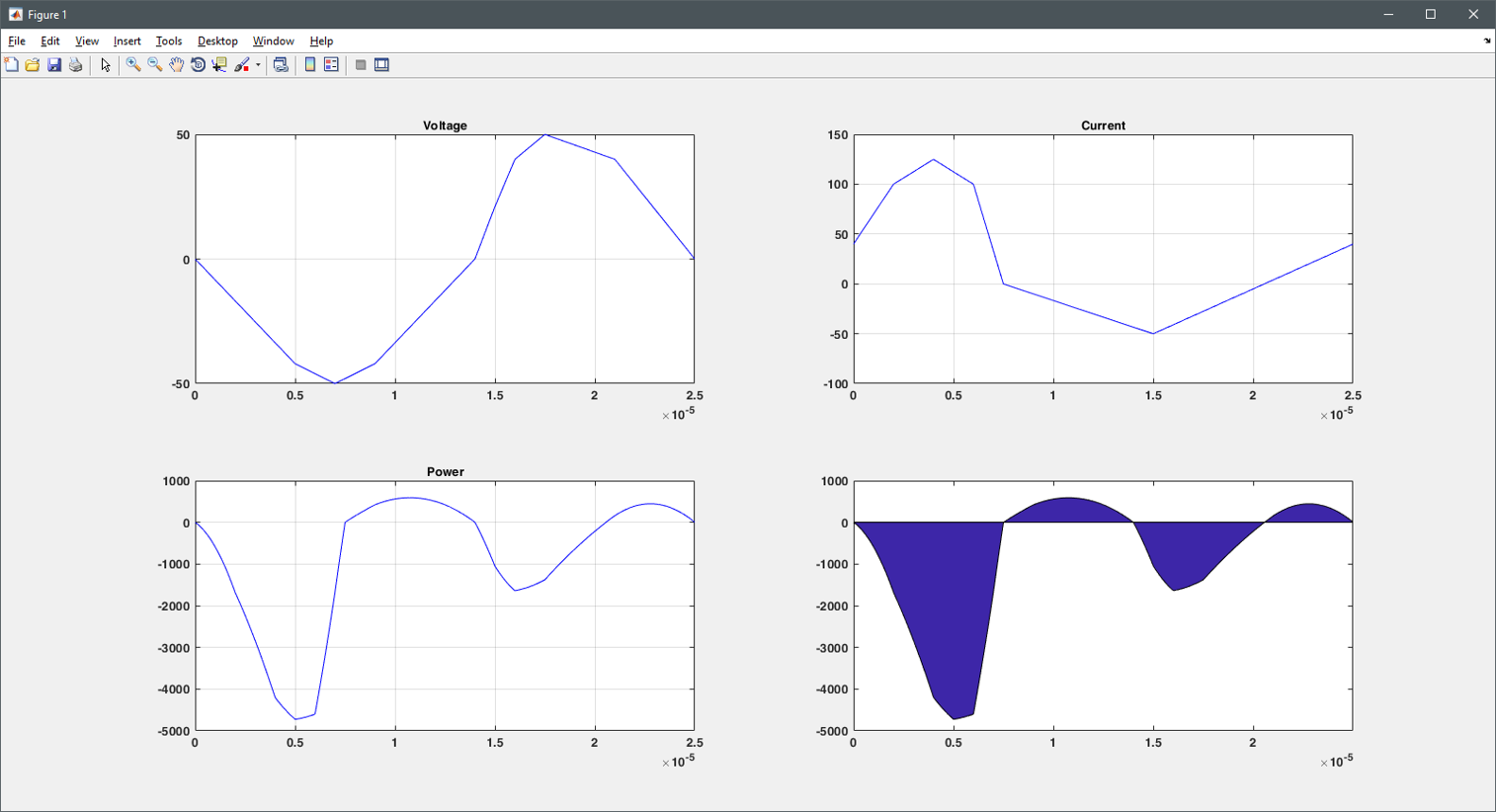

We also tried to calculate the power that we applied by our circuit to the chamber. The plasma was made by a high voltage and the frequency was about 40KHz. To have this voltage with this frequency you should have a transformer, a ferrite core, and two coils. you apply a high current input to the primary input of the transformer then the high voltage is on the secondary end of the transformer. The important thing that matters here is the isolation of the transformer :-), we made and broke about 5 high voltage transformer that had been filled with epoxy :-D we also explode 2 fly-back transformers of CRT TVs.

We use our old oscilloscope to see the voltage and current wave of the high voltage transformer input to estimate the output power of our circuit. We estimate that the plasma power was about 600 Watts.

We use our old oscilloscope to see the voltage and current wave of the high voltage transformer input to estimate the output power of our circuit. We estimate that the plasma power was about 600 Watts.

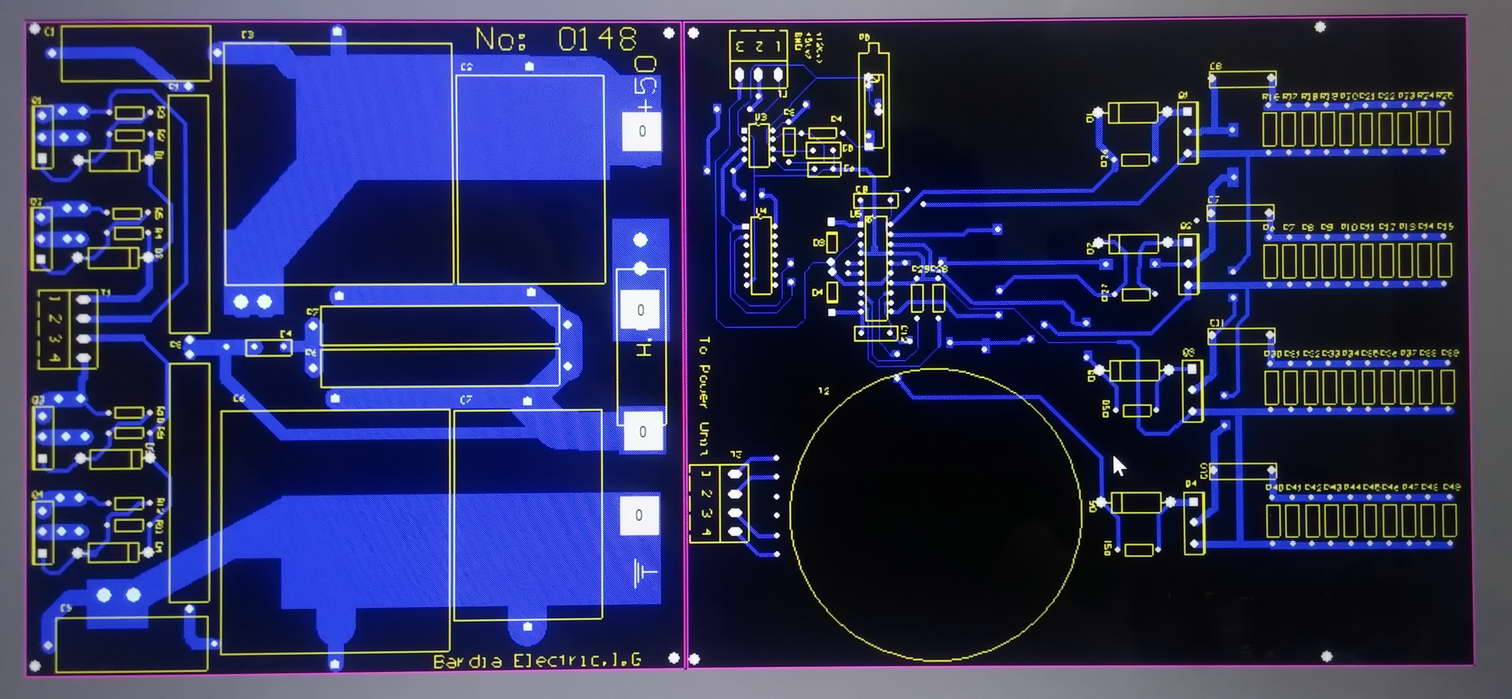

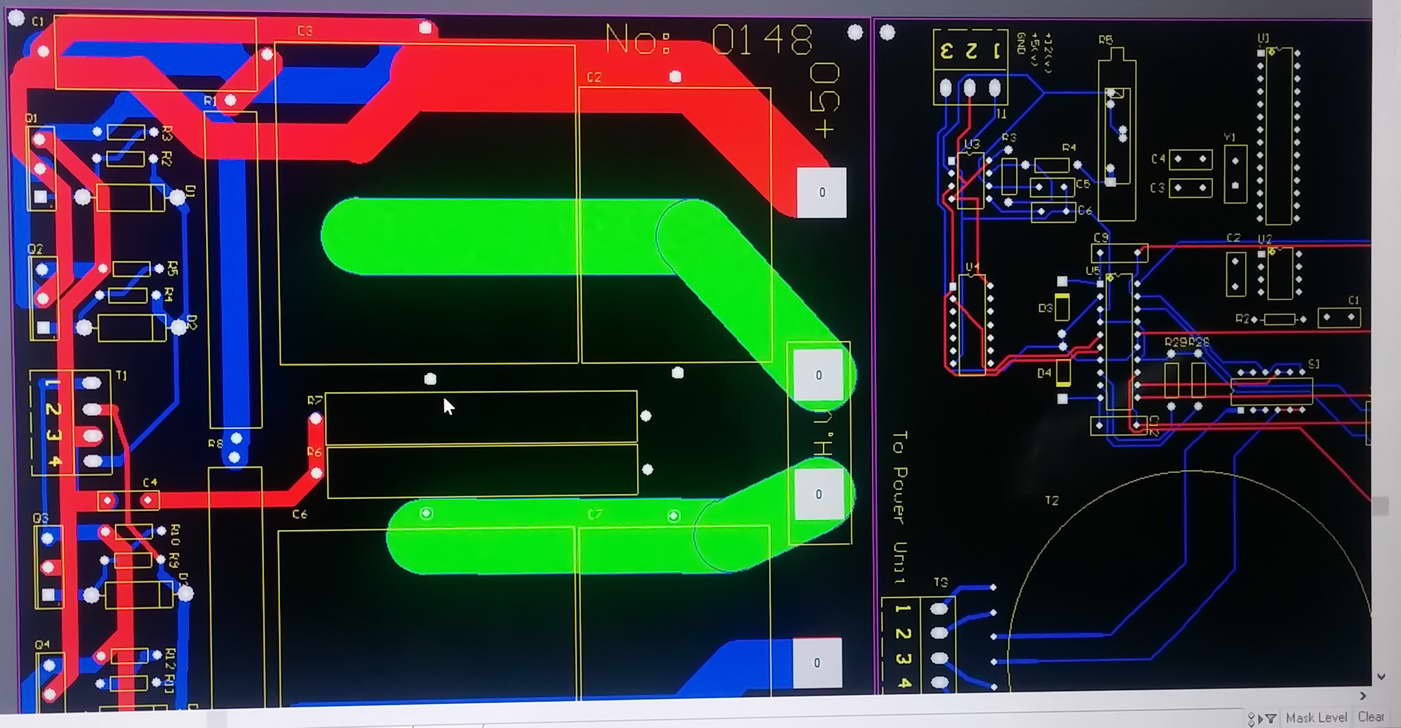

After that we thought that the design of the circuit has been completed we tried to design it in Altium designer to make a PCB for our plasma generator

Our modeling of the evaporator in Autodesk Inventor

We tried so many times, and in the end, we designed our own process successfully.